- ALL COMPUTER, ELECTRONICS AND MECHANICAL COURSES AVAILABLE…. PROJECT GUIDANCE SINCE 2004. FOR FURTHER DETAILS CALL 9443117328

Projects > MECHANICAL/AUTOMOBILE > 2017 > FABRICATION > INDUSTRIAL

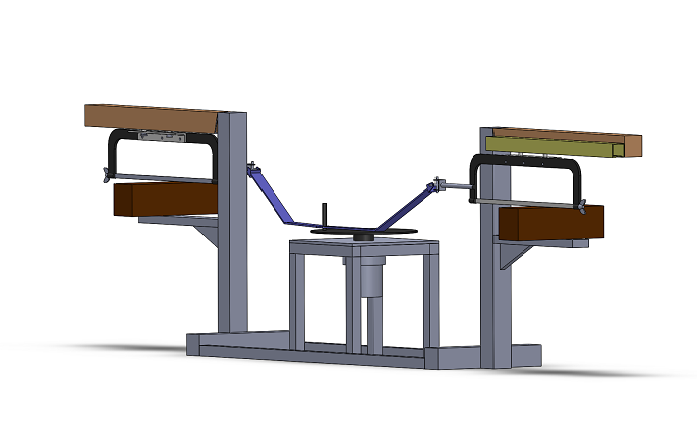

This project is developed for the users for pneumatic shaping hacksaw machine. It consists of pneumatic cylinder, piston, air tank, solenoid valves, gate valve, timing control, hacksaw frame, vice etc. A non return valve is fixed with the air tank so that the user can add compressed air in the air tank. An air gauge is connected with the air tank to display the air pressure in the tank. The delivery hose is connected to the cylinder through a solenoid valve. Another solenoid valve is connected with the cylinder for releasing the air pressure in the returning stroke. The two solenoid valves are alternatively energized by timing control. When the first valve is opened, the compressed air pushes the piston and when the second valve is opened, the air pressure is stopped and due to the force of restoring spring, the piston come back. Thus an alternative linear movement is produced. The hacksaw frame is connected with the other end of the piston. The work piece will be cut easily.

Block Diagram

Line Diagram