- ALL COMPUTER, ELECTRONICS AND MECHANICAL COURSES AVAILABLE…. PROJECT GUIDANCE SINCE 2004. FOR FURTHER DETAILS CALL 9443117328

Projects > MECHANICAL/AUTOMOBILE > 2019 > FABRICATION > INDUSTRIAL

Mostly Conveyers are operated by motor with sensor. Sometimes sensor may malfunction and therefore the timing will be collapsed. But the Geneva mechanism reduces the risk of using sensors for timing operations. This project is developed for the users for fabricating a belt conveyer using Geneva mechanism. It consists of Maltese cross with iron disc pair, Gear motor, wheels, belt drive mechanism etc. The gear motor is connected with the rotating disk. For conveyer operation, two wheels are used. One wheel is connected with the maltese cross and the other is connected with the frame through ball bearing. The belt conveyer is mounted with the two wheels. Geneva mechanism is an accurate indexing mechanism that converts the continuous motion into intermittent motion. Due to the intermittent motion, the conveyer is moved across the two wheels. The movement of the conveyer will be controlled by the Geneva mechanism. The Maltese cross determines the timing when to stop and when to run.

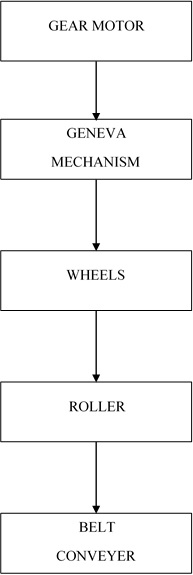

BLOCK DIAGRAM

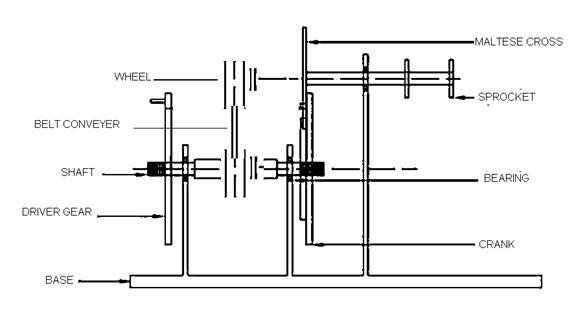

LINE DIAGRAM