- ALL COMPUTER, ELECTRONICS AND MECHANICAL COURSES AVAILABLE…. PROJECT GUIDANCE SINCE 2004. FOR FURTHER DETAILS CALL 9443117328

Projects > MECHANICAL/AUTOMOBILE > 2019 > FABRICATION > INDUSTRIAL

Normally the metal/wood cutting machine is manually hand operated for medium and small scale industries. This project gives an insight about the metal/wood cutting machine. In this project, electromagnet is used for cutting in easy way which can be used in small scale industries at lower cost. The metal/wood cutting machine works with the help of electromagnet. When the handle is pull up the electromagnet is connected to the iron piece so that cutting tool is slightly seemed on the work piece. And also the cutting tool is connected with the motor for rotating cutting tool which is used to cut the metal/wood. To avoid unnecessary accident at work trapped hands in the metal cutting machine, the touch sensor is placed near the rectangular sheet of the work piece. If the sensor senses human’s hand on the work sheet while operating cutting machine, it automatically demagnetize the electromagnet. Demagnetize process is done by relay switch. So that the cutting tool is drop down from the work piece. In manual method sheet metals goes to the scrap sometime because of wrong dimensions, improper cutting etc. The main advantage of intelligent metal cutting machine is to improve product quality, repetition of work, increasing production rate and protect human being from the accident.

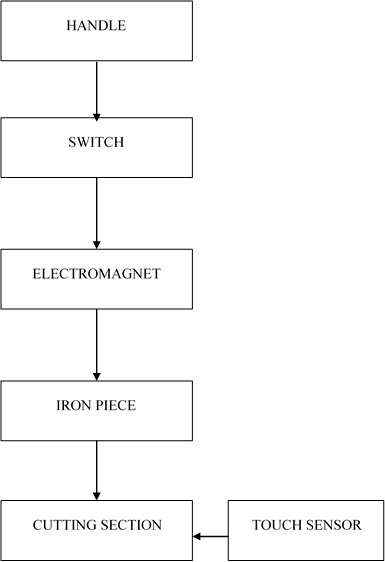

BLOCK DIAGRAM

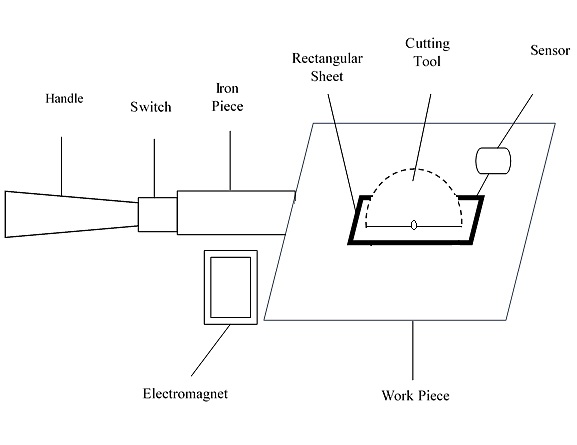

LINE DIAGRAM