- ALL COMPUTER, ELECTRONICS AND MECHANICAL COURSES AVAILABLE…. PROJECT GUIDANCE SINCE 2004. FOR FURTHER DETAILS CALL 9443117328

Projects > MECHANICAL/AUTOMOBILE > 2018 > FABRICATION > INDUSTRIAL

Casting defects are irregularities in the material that have a negative influence on the component; either it is caused from material failure, construction errors or as an effect of process parameters. Defects depend on several factors both in the material, for example the alloy, as well as the surrounding environment such as weather conditions. In the die casting industry today there are many cast defects like shrinkage, porosity and gas blow. This project deals about the cold chamber die casting machine. The main principle is to compress the plastic material in barrel and the compressing motion is developed by rotating the rack and pinion arrangement. The plastic material is heated by the heater surrounding the barrel. Then it is converted into the molten state. The molten plastic is injected through the nozzle in barrel to the die by the compressing force. After completing this process, we will get the product from the die. Commercial products like bushes, couplings, switches etc., can be produced.

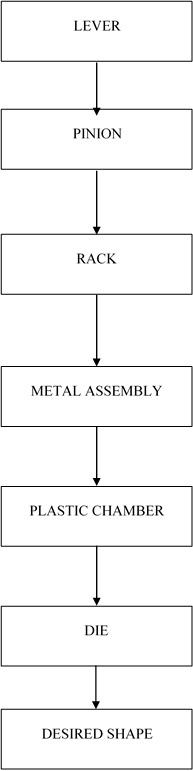

BLOCK DIAGRAM

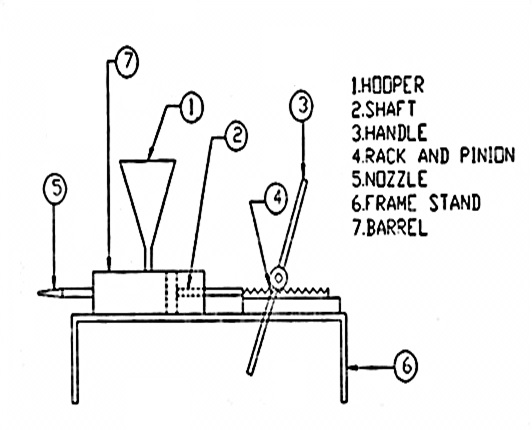

LINE DIAGRAM