- ALL COMPUTER, ELECTRONICS AND MECHANICAL COURSES AVAILABLE…. PROJECT GUIDANCE SINCE 2004. FOR FURTHER DETAILS CALL 9443117328

Projects > MECHANICAL/AUTOMOBILE > 2018 > FABRICATION > INDUSTRIAL

Basically robots are designed in such way that they remove human intervention from labour intensive and hazardous work environment, sometimes they are also used to explore inaccessible work places which are generally impossible to access by humans. The inspection of pipe comes in same category because they carry toxic chemicals, fluids and most of the time has small internal diameter or bends which become inaccessible to human. The complex internal geometry and hazard content constraints of pipes demand robots for inspection of such pipes in order to check corrosion level of pipe, recovery of usable parts from pipe interior, sampling of sludge and scale formation on pipe internal surface etc. Drive control system plays important roles in pipe line robot. In order to inspect the flaw and corrosion of seabed crude oil pipeline, an original mobile pipeline robot with crawler drive unit, power and monitor unit, central control unit, inspection device is developed. Considering the limited space, a compact hardware system is designed based on an ARM processor with controllers. With made-to-order protocol for the crawl robot, an intelligent drive control system is developed. The implementation of the crawl robot demonstrates that the presented drive control scheme can meet the motion control equipment of the underwater pipeline inspection robot.

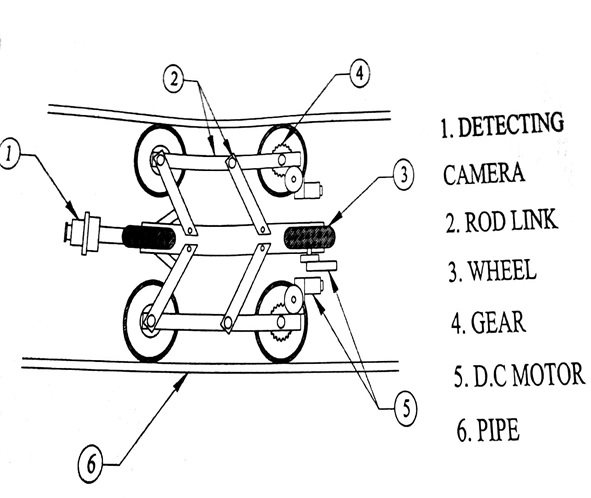

LINE DIAGRAM