- ALL COMPUTER, ELECTRONICS AND MECHANICAL COURSES AVAILABLE…. PROJECT GUIDANCE SINCE 2004. FOR FURTHER DETAILS CALL 9443117328

Projects > MECHANICAL/AUTOMOBILE > 2018 > FABRICATION > INDUSTRIAL

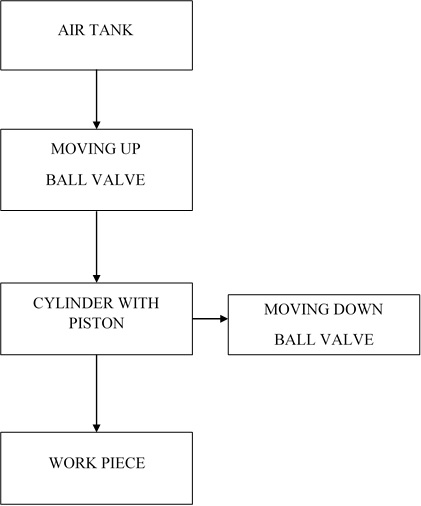

This project is developed for the users to use vice using pneumatic pressure. It mainly consists of air tank, cylinder and piston, ball valve, one way valves, Vice etc. The air tank consists of a ball valve and non-return valve. Air is filled up in the air tank through the non-return valve. A delivery pipe connects the cylinder and piston with the tank through a ball valve (Vice to tight). The two sides of the vice are connected with the ram. When the ball valve is opened, the air from the tank rush out to the cylinder so that the piston moves upwards. Thus the ram connected with the piston moves up. When the ball valve is closed, the ram is stopped at the particular position. Thus the work piece can be tightly fitted within the vice. When the ball valve is closed, the air inside the cylinder is exited out and thus the piston moves down due to the tension of restoring spring. Thus the ram moves down to untighten the work piece.

BLOCK DIAGRAM