- ALL COMPUTER, ELECTRONICS AND MECHANICAL COURSES AVAILABLE…. PROJECT GUIDANCE SINCE 2004. FOR FURTHER DETAILS CALL 9443117328

Projects > MECHANICAL/AUTOMOBILE > 2019 > DESIGN AND ANALYSIS > Thermal analysis

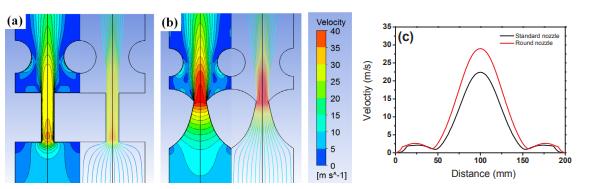

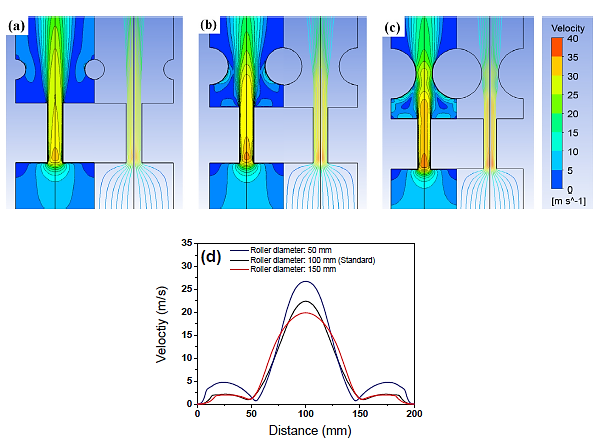

The effects of shape and arrangement of air nozzle in the Stelmor type cooling process on the cooling rate of wire ring were investigated to enhance the cooling rate or cooling performance for wire rod. The influence of nozzle gap, nozzle length, nozzle to roller distance, nozzle shape, nozzle arrangement, and roller diameter was studied by both numerical simulation and the off-line simulator for Stelmor cooling process. Five design concepts for air cooling nozzle were induced based on the results to improve the cooling efficiency. Nozzle gap and length need to be increased, and roller diameter and nozzle to roller distance need to be decreased. In addition, round shaped nozzle with between rollers is necessary to increase the cooling efficiency. The proposed new nozzle based on the five design concepts increased the cooling rate of wire ring by approximately 17% in comparison with the standard nozzle. This new nozzle saves the energy and environment compared to the existing standard nozzle, and the suggested five design concepts give process designers enough data to choose its optimal design options in the Stelmor type cooling process, which is great beneficial in industrial fields.

Image 1