- ALL COMPUTER, ELECTRONICS AND MECHANICAL COURSES AVAILABLE…. PROJECT GUIDANCE SINCE 2004. FOR FURTHER DETAILS CALL 9443117328

Projects > MECHANICAL/AUTOMOBILE > 2019 > DESIGN AND ANALYSIS > STRESS ANALYSIS

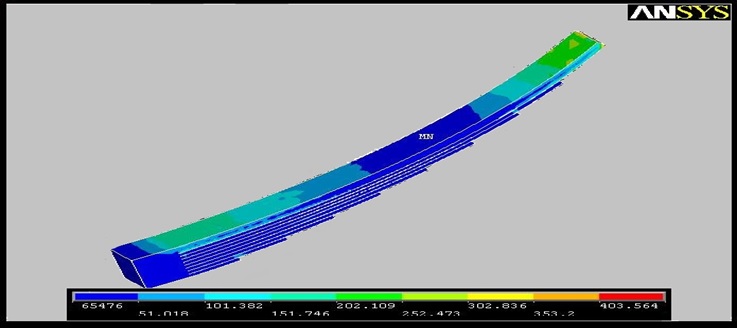

A Leaf spring is used in a four-wheel automobile vehicle as a part of the suspension system. These springs are generally made from steel, which adds a lot of weight to the vehicle leading to a decrease in the efficiency. In the case of lightweight vehicles, things become worse, as the weight of these spring is too heavy it leads to lower performance. In this project, you are going to solve this problem by designing a leaf spring in a solid modeling software and optimizing your design by varying the dimension and type of composite material so that weight will be reduced without compromising the effect needed from the spring. Materials like Iron, Steel are better in tension but poor in compression, similarly Wood, Cast Iron is better in compression but poor in tension. To gain the benefit of having more such properties in one material we combine two or more materials in some arrangement. These types of materials are called composite materials. These composites are generally lighter but strong enough to hold the load. In this project, you need to do research on available composite materials which can be used in leaf spring and can produce the same effect as a steel leaf spring.

Image 1